MiniCal III

Ion-selective measurement of cooling circuits

Ammonia is one of the most commonly used refrigerants, but unfortunately is a strong irritant with corrosive effects. Ammonia's very aggressive reactions in industrial plants often result in damages, such as leaks in copper pipes. Cooling water circuits using this refrigerant must continuously be monitored for leaks to ensure the long-term safety of the systems and, in case of open systems, to comply with environmental protection regulations.

Ammonia leaks must be detected and repaired as quickly as possible to prevent them from causing consequential damage and endangering production processes. Measuring instruments for ammonia detection should therefore be integrated into the secondary cooling circuit. The MiniCal III system was developed specifically for this purpose. Our intensive cooperation with operators of refrigeration plants and our extensive experience have resulted in a powerful system with high usability that is quick and easy to install.

Selective measurement for early warning

The selective measuring method has proven itself reliable for detecting ammonia leaks in direct secondary circuit testing. The MiniCal III system selectively measures leaks (0.2 ppm) even in the smallest concentrations, whether in normal water basins, in circuits or in brine mixtures such as ethylene glycol, propylene glycol, tyfoxit, pekasol, etc.

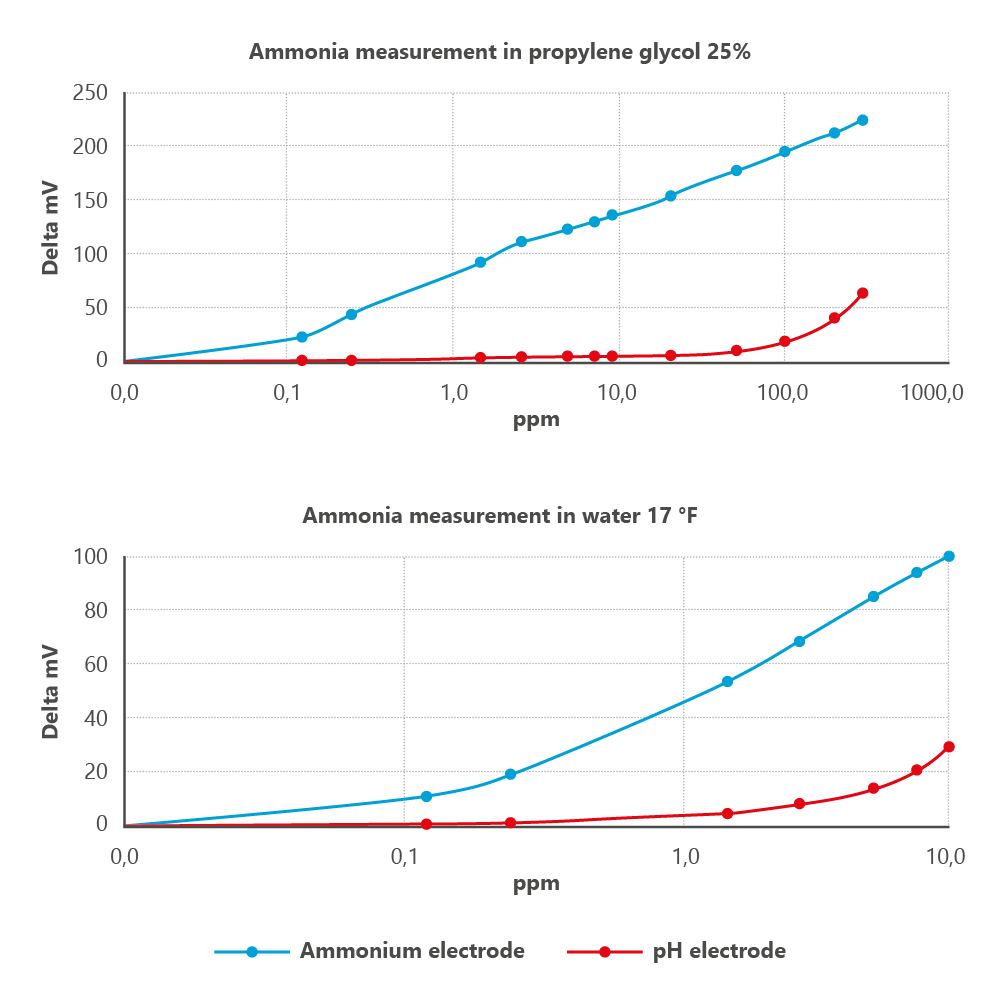

We differentiate between detection in water circuits and water/brine circuits. Electrodes with selective membranes are used in both cases. Depending on the medium and pH value, the reaction of ammonia to the cooling medium is then detected with an ion-selective ammonium electrode or a gas-sensitive ammonia electrode respectively. This allows the detection instrument to make completely reliable statements about any ammonia leakages.

Measurement method

The ion-selective measuring method of the MiniCal III system measures the effective ppm (parts per million) concentration in the cooling circuit. This is very important to prevent damages to the cooling system. Only ion-selective measurements allow for effective detection at the smallest unit of 1 ppm. Safety measures will already have to be initiated at threshold values as small as 3 ppm in open systems (cooling medium from lakes or rivers) and 20 ppm in closed systems.

With selective measuring electrodes, ammonia leaks can be detected reliably and at an early stage. As the diagrams show, detection of ammonia using the pH value is only possible at concentrations above 100 ppm or 1000 ppm ammonia, depending on the medium. The selective measurement method of the MiniCal III system enables warnings at a much earlier stage and thus allows you to initiate appropriate safety measures faster.

PH measurement is not suitable for brine or glycol circuits, since added substances with a basic or acidic effect are buffered. The pH value will thus remain constant until the buffer capacity is exhausted. Any changes in the pH value can therefore only be measured at higher ammonia concentrations.

This measuring technique also has a higher sensitivity in water circuits, so that even smaller leaks can be detected at an early stage.

Signal amplifier

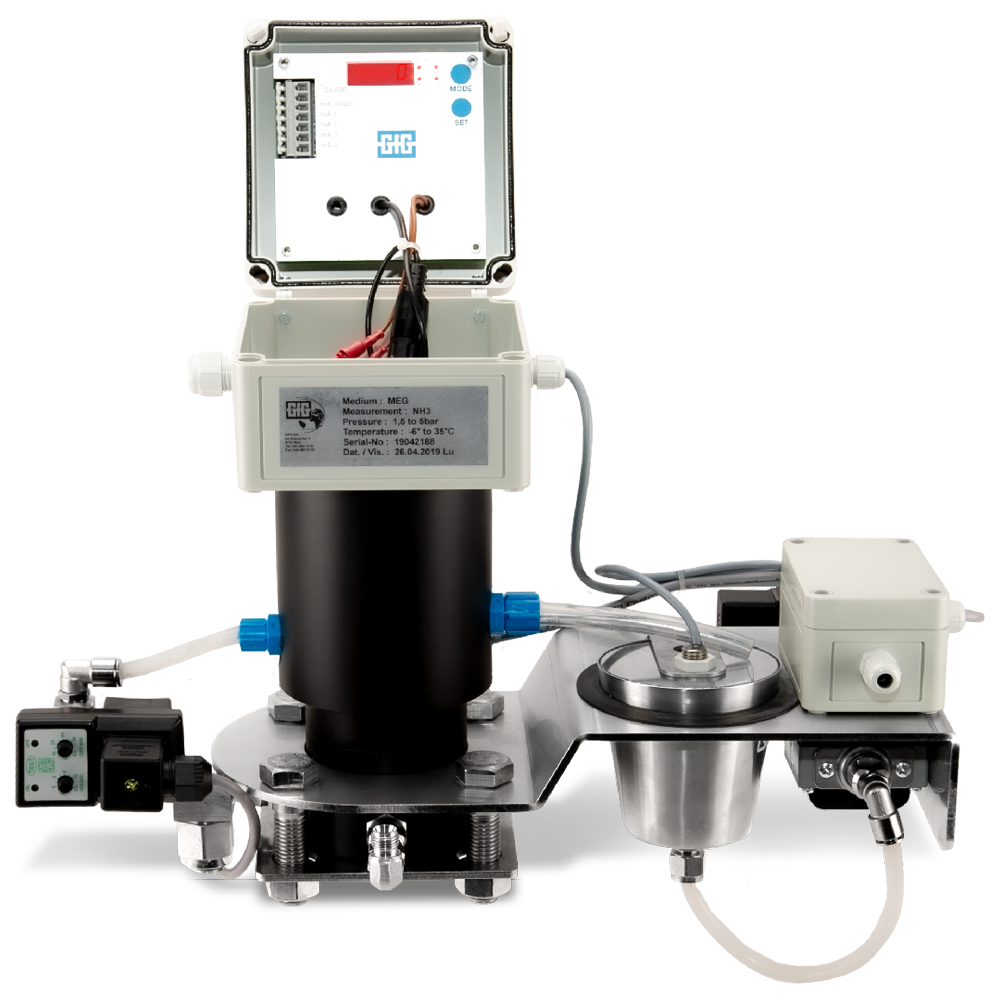

The Mini Cal III system's measuring signal is connected to a measurement amplifier/controller. This conveys the alarms to a higher-level central cooling control. The system will give constant information on the measured concentration and notify you about any exceeded threshold values or flow disruptions and the corresponding operation status they cause. If an alarm threshold value is exceeded, appropriate safety measures will be initiated.

There is also an additional signal pre-amplifier, which is mounted directly on the respective fitting. It provides an on-site display and reduces interferences between the measuring chain and the controller.

Fittings and installation locations

Which MiniCal III fittings are suitable for your system depends on the installation location. The medium is tapped either from pipelines (with recirculation back into the pipelines), in basins or with a free outlet. They can be used flexibly, are easy to install and are characterized by a compact design. You will find a selection at the bottom of this page.

Extensions and accessories

MiniCal III

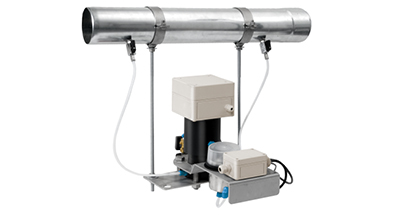

Bypass Fitting

Fitting for monitoring pressure circuits

» more

MiniCal III

Flow Fitting

Fitting for use on unpressurised pipelines

» more

MiniCal III

Immersion Fitting

Fitting for measurements in basins, containers or canals

» more

MiniCal III

CS

Especially for monitoring synthetic refrigerants

» more

Accessories MiniCal III

Here you'll find the complete list of accessories for the MiniCal III

» download PDF