Sensor technologies and measuring principles

There are several different factors that influence which sensor technology is the right choice for your application, inluding the gases you need to measure, their expected concentrations and others, such as ambient conditions, cross-sensitivities to other gases or explosion protection. With our wide range of fixed transmitters, portable gas detectors and different sensors, you are able to reliably monitor combustible and toxic gases, oxygen and volatile vapors.

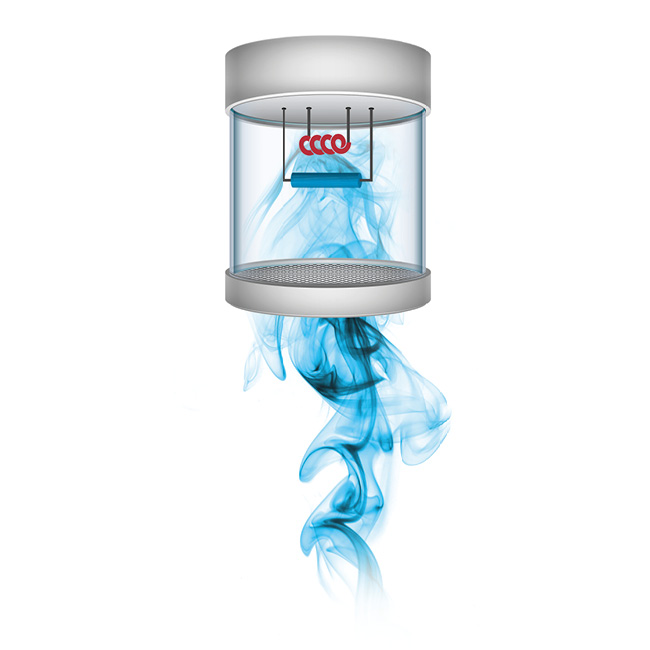

Catalytic Combustion (CC)

Catalytic combustion is a reliable measuring principle for detecting flammable gases and vapors up to the lower explosion limit (LEL). Two sensors (detector and reference) are connected through a "Wheatstone Bridge" circuit. Any combustible gas or gas mixture will burn upon contact with the catalytic detector sensor and oxygen. The heat generated during this process increases the electrical resistance, which produces a current flow that is proportional to the concentration of the combustible gas and can be measured.

- Sum measurement of combustible gases and vapors

- 0 - 100 % LEL

- High measuring accuracy

- Linear display behavior

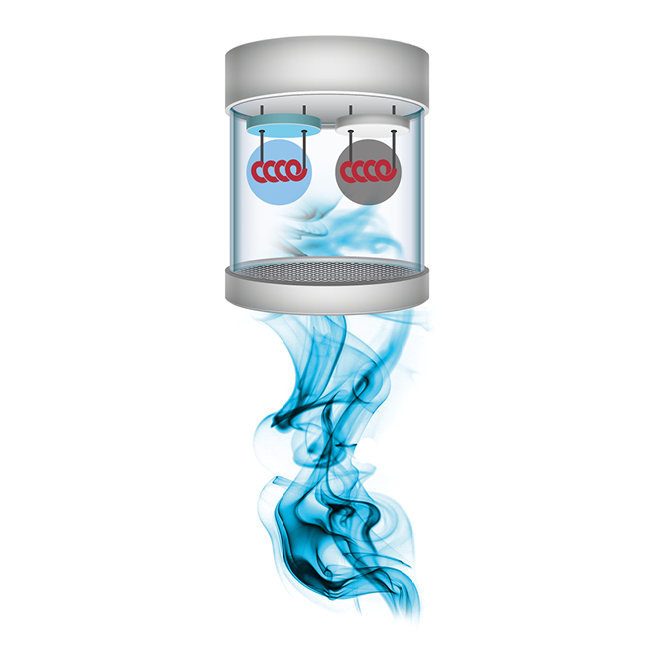

Thermal Conductivity (TC)

The thermal conductivity (TC) principle is used to measure toxic and flammable gases in high concentrations of up to 100% by volume. The way it functions is similar to that of catalytic combustion, including the "Wheatstone's bridge" circuit. The difference between the two is in the measured element: Thermal conductivity does not measure flammability, and consequently does not rely on oxygen being present. A second gas with a different thermal conductivity level, such as air, is therefore required as a reference.

- Toxic and flammable gases

- Wide measuring range (up to 100 vol %)

- Suitable for a variety of applications

Photoionization Detector (PID)

In a photoionization detector (PID), air is absorbed and exposed to ultraviolet light in the sensor. The UV light's photons cause certain molecules to decompose into positively charged ions and electrons. A current flow is thus created between the electrodes in the measuring chamber, which the detector then measures and converts into a value proportional to the gas concentration. Target gases of photoionization are volatile organic compounds (VOCs) such as solvents and petrol, diesel, heating oil or paraffin vapors. These can be dangerous even in very low concentrations. Photoinonization detectors can monitor over 300 of these substances in groups or individually - many even in concentrations of less than 1 ppm.

- Volatile organic compounds

- Short response times

- Very high sensitivity

- Wide range of detectable gases

Zirconium Dioxide (ZD)

This measuring principle uses an electrochemical oxygen pump cell made of zirconium dioxide for oxygen measurement. At high temperatures (> 650 °C), zirconium dioxide behaves like an electrolyte for oxygen, which transports oxygen ions and generates a detectable current in case of a partial pressure difference between the two sides of the membrane. This measuring principle is not susceptible to environmental influences and its results can be indicated in percentages as well as in the trace range (ppm).

- Selective for oxygen

- Very short response time

- Not susceptible to ambient conditions

- Long lifetime

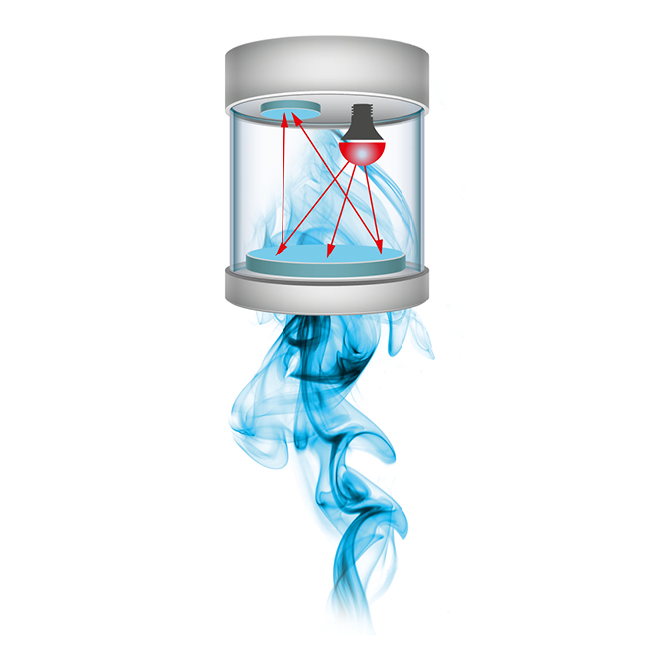

Infrared (IR)

The infrared measuring method utilizes the property of certain gases to absorb light in particular wavelength ranges (bands) - which the main natural components of air (nitrogen, oxygen and argon) cannot do - for measurement. Two infrared beams of different wavelengths (measuring and reference beam) are guided into the measuring chamber where they hit two detectors (measuring and reference detector). If the measuring beam is weakened by the absorption of a present gas, the reduced intensity corresponds to the gas concentration. Gases that can be detected by infrared technology include all heteroatomic gases such as carbon dioxide and hydrocarbon compounds.

- Combustible gases and CO2

- Low cross-sensitivity

- High accuracy

- Long lifetime

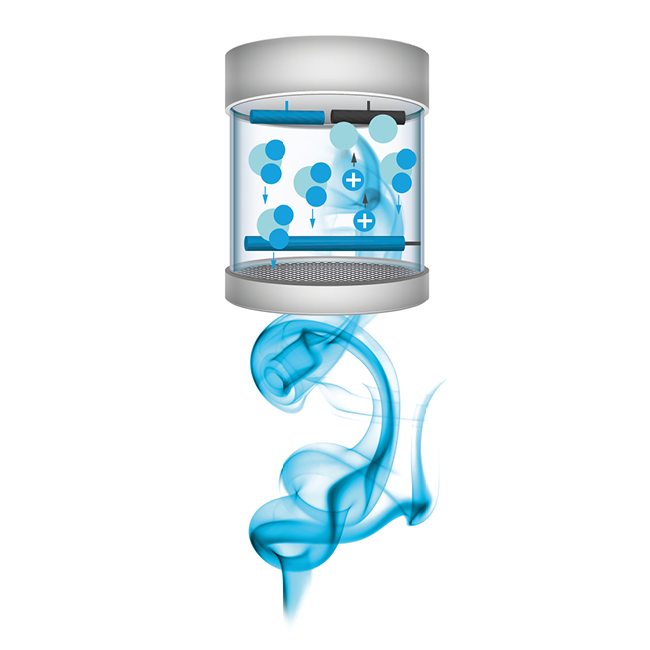

Electrochemical (EC)

An electrochemical sensor is similar to a battery in the way it functions. The gas you need to measure diffuses through a membrane into the sensor, which consists of three electrodes (working, reference and counter electrode) and a conductive electrolyte. The individual components are adapted to the relevant gas. The reaction of gases encountering the working electrode creates a flow of ions to the counter electrode, which is measured and converted to represent the corresponding concentration of the monitored gas. Electrochemical measuring is used to selectively measure one specific gas.

- Toxic gases, O2 and H2

- Linear display behavior

- Very energy efficient

- High sensitivity

Chemisorption (CS)

In chemisorption, the sensor element consists of a metal oxide semiconductor (such as tin dioxide) located in a measuring chamber with a flame arrester. The oxidation of the monitored gas at the sensor element increases the electrical conductivity. The current flow created by this process is then converted into an output signal corresponding to the gas concentration. The temperature of the sensor element is adjusted according to the gas being monitored. Chemisorption is suitable for detecting a wide range of combustible and toxic gases. It is characterised by its long-life sensors and low cost.

- Flammable and toxic gases

- Cost-effective

- Different measuring ranges (vol %, LEL, ppm)

- Long lifetime