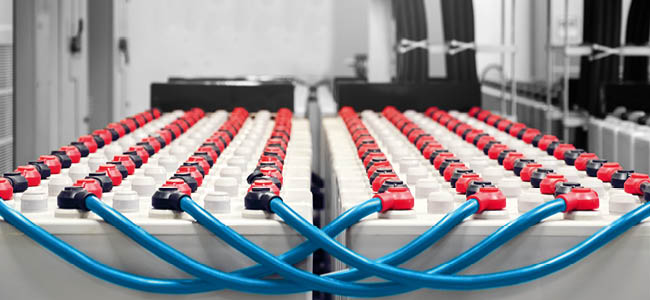

Lithium-Ion Battery Manufacturing

Lithium-ion battery production is a key technology for e-mobility and energy storage. The manufacturing process involves highly sensitive chemical substances, flammable electrolytes, and inert atmospheres. Formation, testing, recycling, and maintenance work in enclosed production areas present significant risks for employees due to toxic, flammable, and oxygen-displacing gases. With GfG’s portable gas detectors and fixed monitoring systems, hazardous atmospheres can be reliably detected before they become a safety or production risk.

Gas monitoring in lithium-ion battery production

Battery cell production includes electrolyte filling, formation charging, aging, and quality testing. During these processes, hydrogen, carbon monoxide, solvent vapors, and decomposition gases may be released. In dry rooms and glovebox systems, nitrogen atmospheres can additionally lead to dangerous oxygen deficiency.

Before maintenance work or entry into enclosed systems, atmosphere testing is essential. Portable gas detectors with an integrated pump enable safe pre-entry measurements in battery modules, formation chambers, and technical installations. For continuous personal protection in production areas, compact multi-gas detectors support the early detection of hazardous gas concentrations.

Fixed gas detection systems provide continuous monitoring in electrolyte handling areas, formation zones, and recycling facilities, where toxic gases, flammable vapors, or oxygen deficiency may occur during different production steps or in storage areas.

Potential dangers:

» hydrogen

» carbon monoxide

» toxic electrolyte vapors (VOCs, HF)

» oxygen deficiency

» flammable gas mixtures

» confined production and processing areas

To our gas detectors

Water Measurement Technology