Industrial Manufacturing

Industrial manufacturing facilities operate a wide range of production processes involving chemicals, fuels, heat, and mechanical equipment. Depending on the industry sector, hazardous gases may be released during normal operation, maintenance, or unplanned process deviations. Gas detection plays a key role in protecting personnel, minimizing downtime, and supporting safe and efficient production.

Gas monitoring in industrial manufacturing

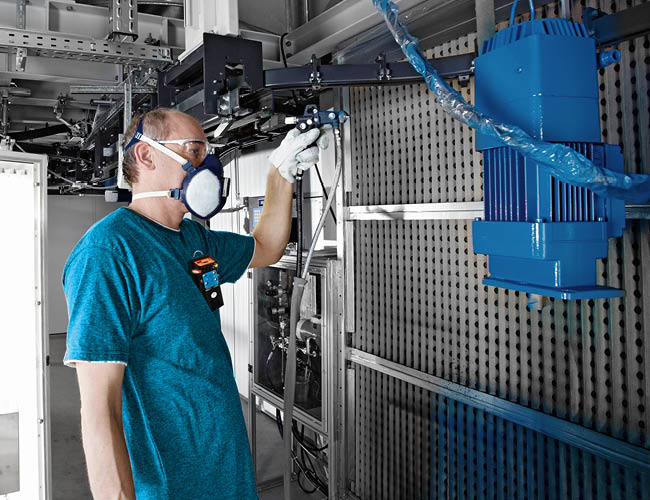

Manufacturing environments such as metal processing, plastics production, surface treatment, food processing, and general assembly plants may involve the use or generation of combustible, toxic, or asphyxiating gases. Typical risk areas include production lines, technical rooms, storage areas, process enclosures, and exhaust systems. Fixed gas detection systems provide continuous monitoring in areas where gas hazards may occur permanently or repeatedly. They enable early detection of leaks or abnormal process conditions and support automated safety responses such as ventilation or shutdown functions. Portable gas detectors are used during maintenance, inspection, and repair work, especially when personnel enter enclosed machinery, pits, or technical installations. They support pre-entry testing and provide personal protection in changing or temporary work environments.

Potential dangers:

» combustible gases and vapors

» toxic gases

» oxygen deficiency

» process-related gas releases

» enclosed machinery and technical areas

To our gas detectors

Water Measurement Technology