Question:

I was at a chemical factory for explosivity testing and I used a G450 multi gas meter (last factory calibrated earlier this year and field calibrated on site). The chemicals they had were mostly alcohol based liquids. I expected it would pick up some LEL%, but LEL% stayed at zero even when I placed the probe inside the alcohol-based liquid containers. However, elevated CO levels were detected instead. There were neither gasoline-operated equipment nore combustion sources in the area. I am wondering if alcohol vapor can trigger CO sensors?

Answer:

All electrochemical CO sensors, regardless of the brand or model, respond to high concentrations of alcohol vapor.

CO sensors have an internal filter designed to absorb interfering vapors from VOCs such as alcohols. The filter is sufficient to protect the sensing electrode in the CO sensor from low concentrations, but once the filter is saturated, the alcohol will break through the filter, and the sensor will begin to respond. Once breakthrough has occurred, CO sensor readings typically continue to slowly climb even after the source is removed from the atmosphere being sampled. This is due to VOC slowly being released from the saturated filter into the sensor. Given time, the sensor usually recovers in fresh air without permanent damage. However, depending on the concentration of the exposure, complete recovery can sometimes take several hours, or even overnight. So, it is better not to unnecessarily expose the CO sensor to high concentration alcohol vapor.

The response of the LEL sensor to alcohol vapor is affected by the calibration gas that is used to calibrate the instrument, and the measurement scale you use to display the LEL readings.

The standard calibration gas used to calibrate G450 instruments used in general confined space entry applications contains 50% LEL (2.5% volume) methane. LEL readings are normally displayed in %LEL methane (CH4) increments. Compared to methane, the relative response of the LEL sensor to ethanol is about 80%. That means, the uncorrected reading for ethanol will be lower than the reading for an equivalent concentration of methane. More importantly, however, is the speed of response of the sensor to ethanol compared to methane.

In general, the larger the molecule, the lower the relative response, and the slower the response of the CC LEL sensor. Application note AP1018 that posted on our website that explains combustible sensor performance in greater detail.

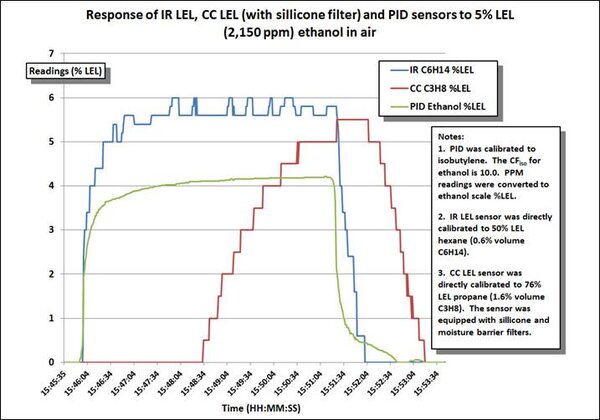

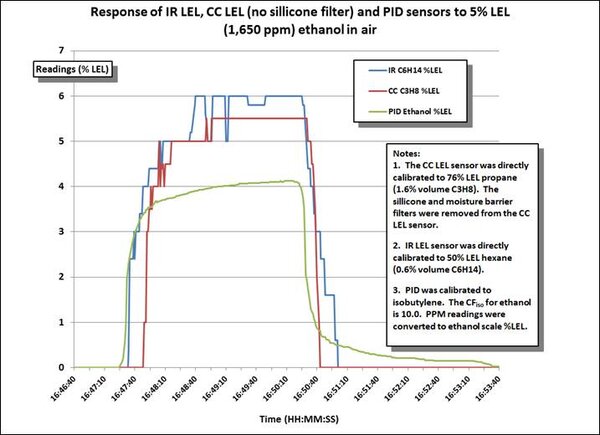

Also, on a standard basis, the LEL sensors in general purpose G450 confined space instruments are equipped with a protective external filter designed to remove silicone vapors, (a virulent combustible sensor poison). The presence of the filter slows the diffusion of ethanol vapor into the sensor. The following two graphs show the response of the catalytic combustion (CC) LEL sensor with and without the protective filter. As you can see, with or without the filter the CC LEL sensor responds accurately to ethanol, but with the filter in place it takes longer. The instruments in the charts were equipped with PID and infrared (IR) LEL sensors as well as standard CC LEL sensors. Neither the PID nor the IR LEL sensor is equipped with an external filter, so they provide a good baseline for comparison with the CC LEL sensor.

For your client, assuming that alcohols are the most significant LEL vapors of interest, I would make the following recommendations:

- The instrument should be calibrated and operated using the propane scale. I would suggest using GfG 50% LEL propane equivalent calibration gas for this purpose. You will need to change the instrument settings for the combustible sensor scale from “methane” to “propane”.

- I suggest removing the protective external silicone filter from their LEL sensor. This is a very simple procedure. Our Service Department can talk you through the procedure over the telephone. All you need to do is access the combustible sensor, peel back the protective moisture barrier filter, (which exposes the silicone filter), remove the silicone filter material, and replace the moisture barrier filter.

- We have an alternative CO sensor available for use with the G450 that is more resistant to exposure to alcohol vapors. It also recovers more quickly after high exposures. If response of the CO sensor to alcohol appears to be an issue, I suggest replacing the standard CO sensor in your customer’s instrument with our CO-H (City Technology 2CF) CO sensor.

- When measuring ethanol vapor you must give the CC LEL sensor enough time to reach a final stable reading, however much time it takes, before taking action based on the readings. Remember to build this into your customer’s procedures. Also, remember that the amount of time it takes for the instrument to respond is also affected by the length of sample tubing. The motorized pump draws the sample through the tubing at a rate of about 1 foot per second. The sample has to reach the sensors before they can begin to respond.

Please call the GfG Service Department at 800-959-0329 for assistance with making these modifications, or ordering the new propane scale calibration gas.

Thank you for your question.