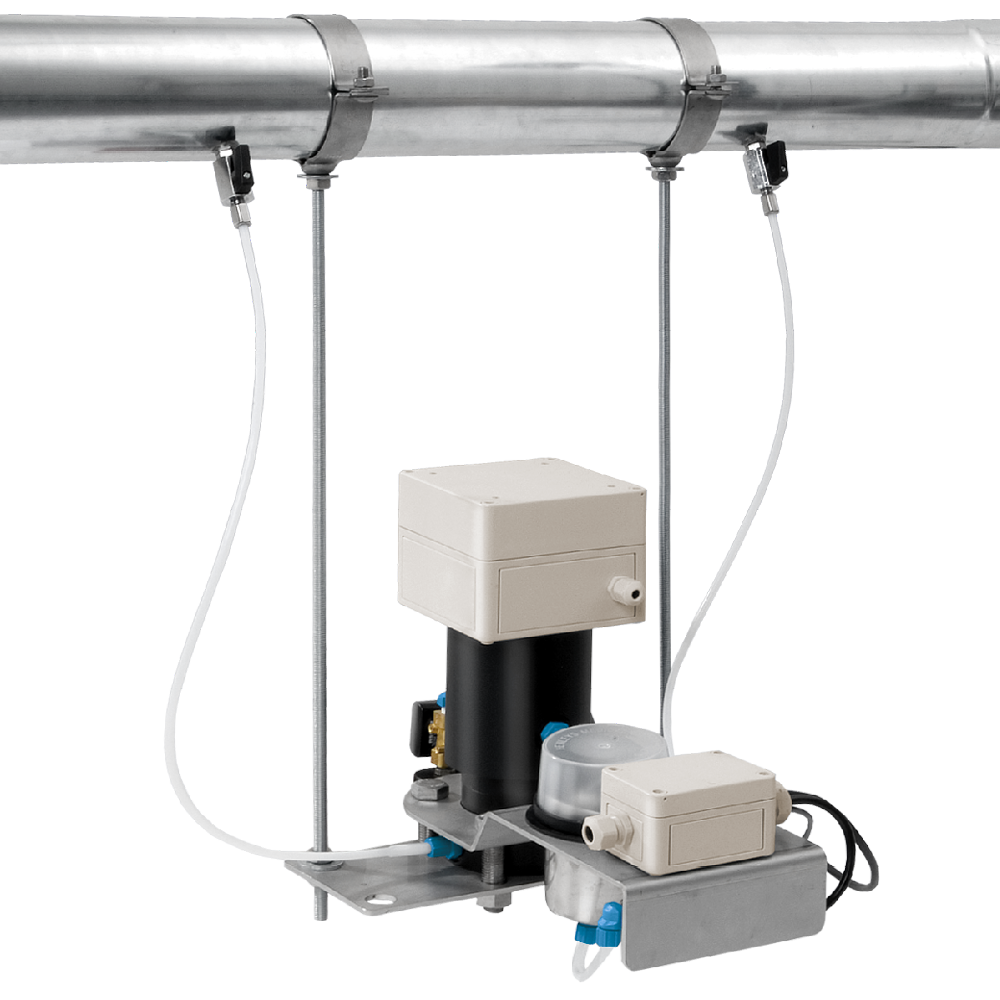

MiniCal III Bypass Fitting

The bypass fitting was designed for monitoring ammonia leaks in pressure lines. It is an innovative system which allows you to commission, service and maintain devicces without interrupting your processes.

Samples of the medium are guided through the MiniCal III bypass fitting and then guided back into the pipeline. This will give you more flexibility regarding the installation location. Depending on the local conditions, the fitting is mounted either below the pipeline or on the wall.

The medium in the measuring chamber must be exchanged regularly to ensure early detection of any ammonia leaks. Samples of the medium are guided through the fitting as soon as the upstream solenoid valve is opened. A regular exchange of the medium can thus be achieved by setting the interval and the opening time of the solenoid valve. As soon as the analysis of the sample is completed, it is pumped back into the circuit by a high-pressure pump to avoid any loss of coolant.

The flow can thus be tested by monitoring the pump and the solenoid valve. The bypass fitting is designed for use in a pressure range of 1 to 6/10 bar and a temperature range of -10°C to +50°C.

Key features at a glance:

- Flow monitoring

- Regular medium exchange

- No loss of coolant

- Simple installation and operation

- Measurement in pipelines from 1 to 6/10 bar

- Signal preamplifier/microprocessor mounted on fitting in housing

- Service and maintenance without process interruption

- Output signal 4-20 mA

Extensions and accessories

MiniCal III

Basics

Ion-selective ammonia measurement of cooling circuits

» more

MiniCal III

Flow Fitting

Fitting for use on unpressurised pipelines

» more

MiniCal III

Immersion Fitting

Fitting for measurements in basins, containers or canals

» more

MiniCal III

CS

Especially for monitoring synthetic refrigerants

» more

Accessories MiniCal III

Here you'll find the complete list of accessories for the MiniCal III

» download PDF